The demand for castings is based on the nature of cast iron as engineering materials and their economic cost advantages. Cast irons offers a tremendous range of the metallic properties of strength, hardness, machinability, wear resistance, abrasion resistance, corrosion resistance and other properties. Furthermore, the foundry properties of cast irons in terms of yield, fluidity, shrinkage, casting soundness, ease of production and others make the material highly desirable for casting purposes.in general, a cast iron is an alloy of iron ,carbon (up to 4 per cent) and silicon (up to about 3.5 per cent) which ordinarily is not usefully malleable as cast.

Gray Cast Iron

Because of a fortunate combination of engineering properties, availability, excellent casting characteristics and favourable cost, grey irons are produced in tonnages exceeding all other castings. Gray cast iron is having a chemical composition such that after solidification, a large portion of its carbon is distributed throughout the casting as free or graphic carbon in “flake form". Gray cast iron always presents a Gray sooty surface when fractured.

Physical properties of grey cast iron

- Compressive strength: This is an outstanding property of Gray cast iron, being 3 to 5 time greater than its tensile strength.

- Torsional strength: Strength in torsion is about 1.2 to 1.4 times the strength in tension.

- Elasticity: The elastic modulus in tension varies from 12 to 22 million psi depending on microstructure on the iron.

- Endurance Limit: the endurance limit of Gray iron is about 35 to 50 per cent of its tensile strength. However, because it is less sensitive to notches, its endurance limit is as great in many application as that of materials of substantially higher tensile strength.

- Wear resistance: Gray iron is outstanding in its resistance to the sliding friction types of wear, especially lubricated. This is exemplified in its use for piston rings, cylinder liner, crankshaft, clutch plates, break drums, gears and internal combustion engine block.

- Machinability: Gray iron is among the most machinable of ferrous materials. Best machinability in Gray irons in the softer irons. A hardness range of 130 to 240 BHN encompasses most Gray irons.

- Damping : damping capacity is the ability of a material to absorb energy due to vibrations and thus dampen the vibrations. The vibration damping capacity of Gray iron assists markedly in producing smoothness of operation in IC engines or other structure where vibration is an operating characteristics.

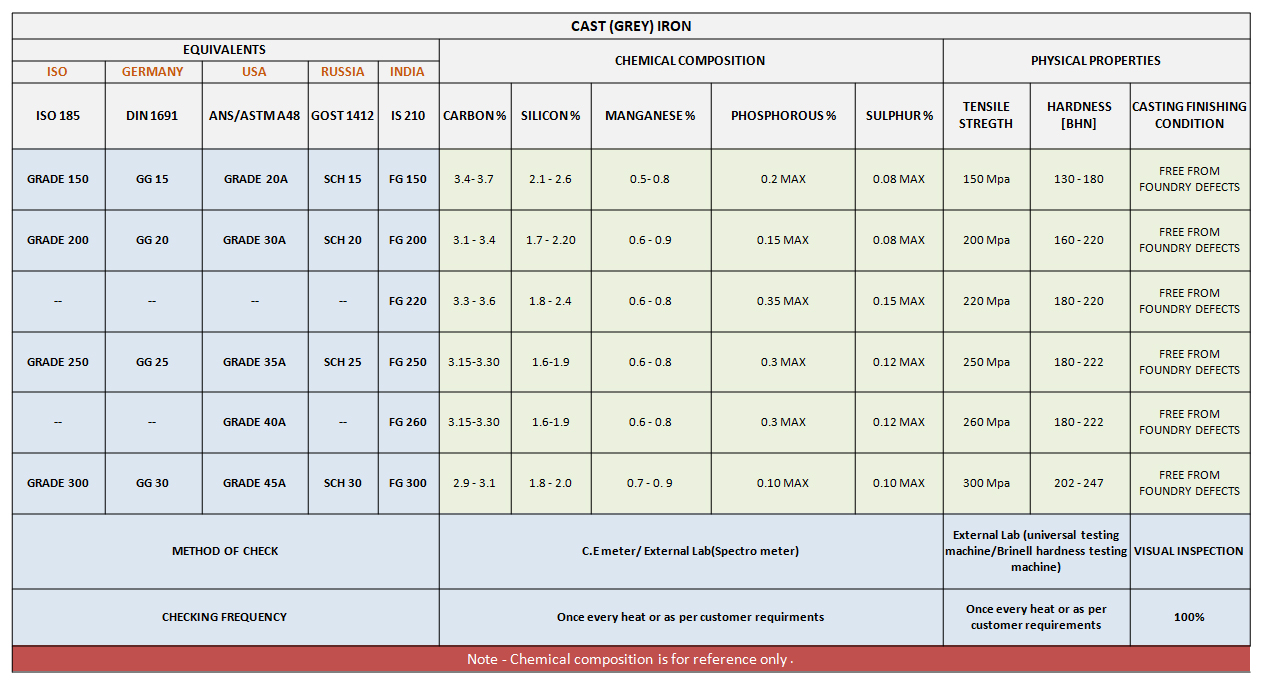

Specification for Grey cast Iron

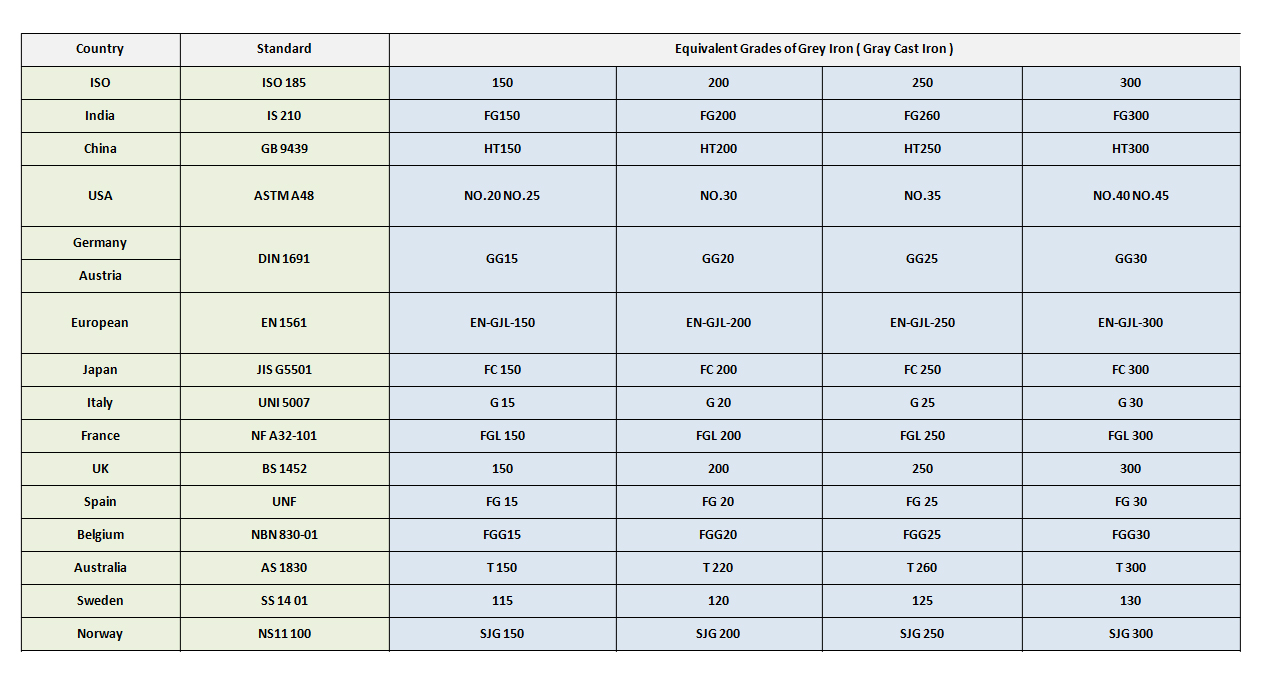

Grey Cast Iron Equivalents